Embark on a thought-provoking expedition into sustainability within the fashion industry with our series on Images Business of Fashion. In this series, we traverse the intricate pathways of visionary brands committed to reshaping the narrative of fashion through sustainable initiatives. As we journey forward, we uncover the strategies and the profound ethos that propels these brands toward a greener, more responsible future.

In each installment, we unravel the layers of innovation, dedication, and conscious decision-making that define the leadership of these brands. From reimagining supply chains to championing eco-friendly materials, these trailblazers exemplify a paradigm shift towards a more sustainable and ethical fashion landscape.

This week, IMAGES Business of Fashion explores sustainability initiatives by Ralph Lauren, unveiling their innovative strides in reshaping the fashion industry.

Ralph Lauren Corporation is a global leader in the design, marketing and distribution of luxury lifestyle products in five categories: apparel, footwear & accessories, home, fragrances and hospitality. Ralph Lauren started the business in 1967 in a tiny office at the Empire State building and for more than 50 years, he has sought to inspire the dream of a better life through authenticity and timeless style. Its reputation and distinctive image have been developed across a wide range of products, brands, distribution channels and international markets.

The company’s brand names – which include Ralph Lauren, Ralph Lauren Collection, Ralph Lauren Purple Label, Polo Ralph Lauren, Double RL, Lauren Ralph Lauren, Polo Ralph Lauren Children and Chaps, among others – constitute one of the world’s most widely recognized families of consumer brands.

The Timeline

The Timeline

Ralph Lauren started his business in 1967 with the launch of a neckwear line under the name Polo. Over the next year, the brand debuted its first full men’s collection. By 1970, The Polo by Ralph Lauren shop opens in Bloomingdale’s and in the very next year, he opened his first standalone store. The iconic Polo Pony debuted on the cuff of a new line of women’s shirts.

In 1972, he introduced the Polo shirt and in 1976, won a Coty Award for womenswear and the Coty Hall of Fame Award for menswear. Soon after, in 1976, he introduced Polo for Men.

Three years later in 1981, Ralph Lauren opened his first store outside the United States. From then on, it was all accolades. In 1986, Ralph Lauren redefined retail with his first flagship store and in 1991, he received the CFDA Lifetime Achievement Award. Soon after, in 1995, the brand introduced Purple Label and the Launch of Ralph Lauren Paint.

Over the next decade, the brand was the official outfitter of Wimbledon in 2006 and in 2008, the official outfitter of Team USA and in 2018, the outfitter at the Olympic Winter Games PyeongChang 2018. All this while, his foreign expansion continued with flagship stores in countries all over the world. He even diversified into the restaurant business.

India Presence

- Ralph Lauren has license agreement with Aditya Birla Fashion and Retail Limited (ABFRL) for the opening of franchisee brick-and-mortar outlets in India.

- Over the next five to six years, Ralph Lauren is aiming to open 15-16 stores in India.

- Currently, it has two stores in India.

- Ralph Lauren products are currently available online in India on leading e-commerce sites like Amazon and Myntra.

The Sustainability Approach

Ralph Lauren’s approach has been on creating a business that is timeless and has a positive impact on tomorrow. It strives to do business in ways which respect the planet by using renewable energy, managing the waste properly and using water responsibly. The objectives are:

- Ensure the design, production and merchant teams receive annual training on sustainable, circular, inclusive and culturally aware design.

- Offer high quality products made with 100% recycled cotton by 2025.

- Achieve 100% sustainably sourced key materials by 2025.

Sustainability Platform

- Ralph Lauren has debuted Color on Demand, a multi-phased system with an aim to deliver the world’s first scalable zero waste water cotton dyeing system.

- Colour on Demand is composed of technologies that enable the recycling and reuse of all water from the dyeing process. It also dramatically reduces the amount of chemicals, dye, time and energy used in the cotton dyeing process.

- As part of the first phase of Color on Demand, Ralph Lauren optimized the use of Ecofast Pure Sustainable Textile Treatment, a pre-treatment solution developed by Dow for cotton textiles. When used with existing dyeing equipment, it enables the use of up to 40 percent less water, 85 percent fewer chemicals, 90 percent less energy and a 60 percent reduction in carbon footprint compared with traditional cotton dyeing processes.

Sustainable Innovation in Sportswear

Sustainable Innovation in Sportswear

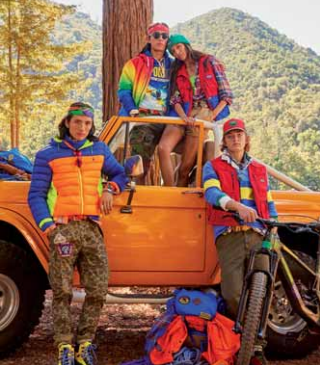

In FY22, the brand enjoyed success through two separate endeavors in the world of sport. First, the partnership with Natural Fiber Welding was on display at the 2022 Australian Open with the launch of the RLX CLARUS®Polo Shirt. The shirt featured a high-performance cotton that performs similarly to plastic based synthetic fabrics.

Second, Ralph Lauren continued partnership with the U.S. Olympic and Paralympic teams as their official Openingand Closing Ceremonies outfitter. These winter collections featured a range of sustainable materials and traceable production practices, including the use of recycled polyester, nylon and down along with Responsible WoolStandard (RWS)-certified, U.S.-grown wool. The brand made dress of more than 1,000 members of Team USA, who competed in Beijing.

Sustainability: The Year (2022) in Review

- Transitioned 95% of Ralph Lauren Home core bedding and bath and new fashion bedding to cotton qualities, considered sustainable, such as organic or Better Cotton.

- 77% of the units produced in FY22 met at least one sustainable material criterion — up from 33% in FY21.

- Established an internal design with intent department focused on culturally sustainable design, product development and story telling.

- Continued with the commitment to full transparency with disclosure of Tier I factories and processing units covering 98% of the business.

- Open-sourced the ECOFAST™ Manual to improve dyeing process and accelerate change in the industry and launched Color on demand as part of the in-store experience.

- Achieved 92% waste diversion rate in the North America-owned distribution centers, including diverting more than 17,000 pounds of hangers at the North Carolina distribution center from landfill by working with local recycling vendors.